Introduction :

In an era dominated by smartphones, the demand for mobile phone screen installation has skyrocketed. Whether due to accidental drops, cracked screens, or hardware malfunctions, many users find themselves in need of professional assistance to restore their devices to full functionality. This article delves into the intricate process of mobile phone screen installation, highlighting the precision, expertise, and attention to detail required to achieve a seamless repair.

Section 1: Assessing the Damage and Device Compatibility:

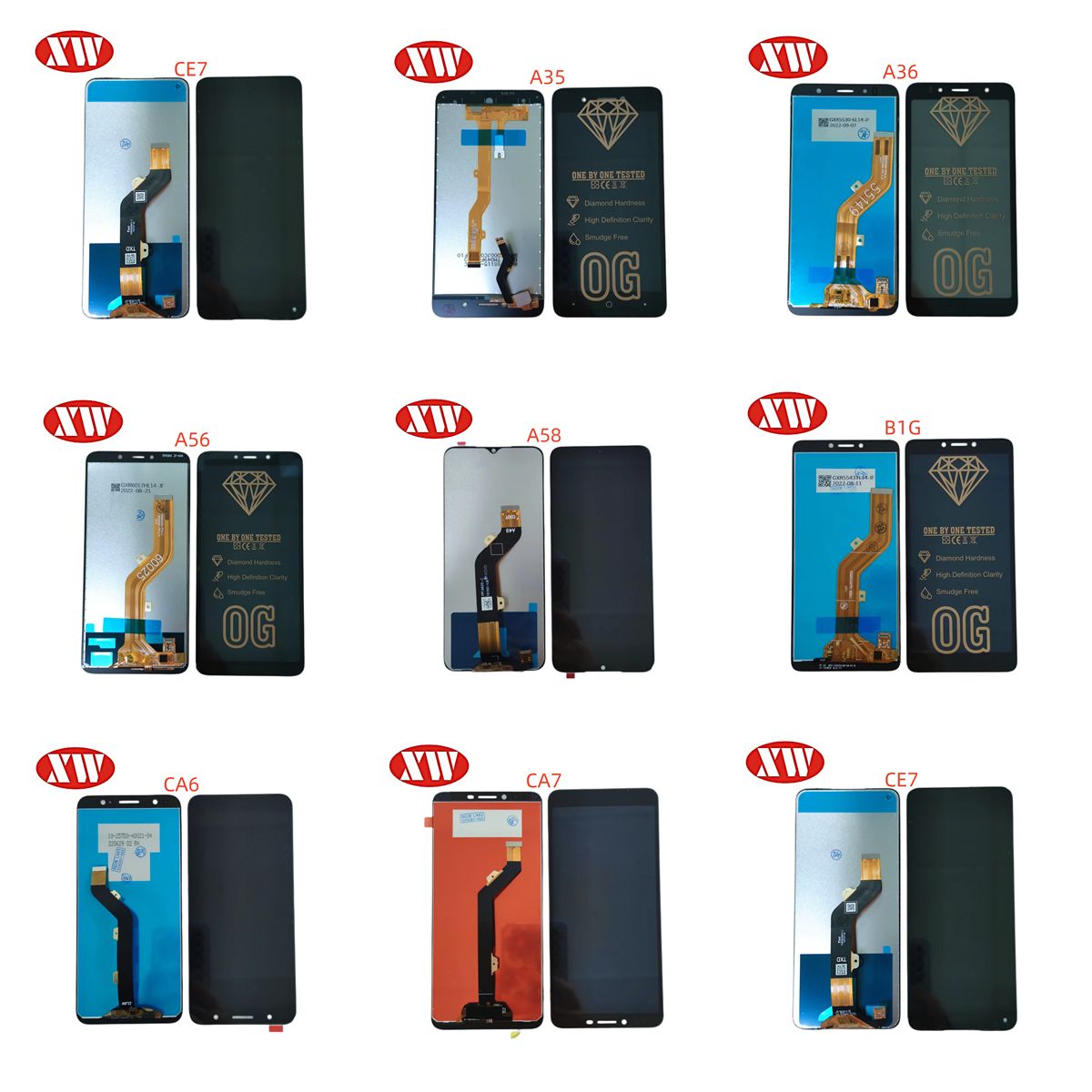

Before embarking on a mobile phone screen installation, a skilled technician must conduct a thorough assessment of the damage. This involves identifying any external cracks, shattered glass, or malfunctioning display components. Moreover, compatibility is a crucial factor in ensuring a successful repair. Mobile phones come in various models, each with unique screen specifications. Technicians must verify that the replacement screen is compatible with the specific device in question, considering aspects such as screen size, resolution, and touch sensitivity. This attention to detail guarantees that the new screen will seamlessly integrate with the phone’s existing hardware and software.

Section 2: Tools of the Trade :

Performing a mobile phone screen installation requires specialized tools to ensure a smooth and safe repair process. These tools include screwdrivers, pry tools, suction cups, heat guns, and precision tweezers. Each tool serves a specific purpose, enabling technicians to disassemble the phone, remove the damaged screen, and install the new one. For instance, heat guns are used to soften the adhesive securing the screen, while suction cups provide a reliable grip for removing the broken display. Precision tweezers aid in delicate maneuvers, such as reconnecting tiny ribbon cables. The expertise of the technician lies not only in their knowledge of these tools but also in their ability to use them efficiently and effectively to minimize the risk of further damage to the device.

Section 3: Precise Disassembly and Connection :

Once the damaged screen has been properly assessed and the necessary tools are at hand, the technician proceeds with the disassembly process. This step requires extreme caution to prevent unintended harm to the phone’s internal components. It is vital to follow a meticulous approach, unscrewing the device, removing the battery if necessary, and disconnecting delicate ribbon cables that connect the screen to the motherboard. A single misstep can lead to irreversible damage or result in the loss of crucial data.

With the old screen removed, the technician then moves on to connecting the new screen. This step demands precision and patience as each cable and connector must be aligned and secured correctly. Improper alignment or loose connections can lead to display issues, unresponsiveness, or reduced touch sensitivity. The technician ensures that the screen is positioned flawlessly within the phone’s frame, aligning the connectors and cables meticulously before reassembling the device.

Section 4: Final Testing and Quality Assurance :

After the installation process is complete, a comprehensive testing phase is essential to ensure the success of the repair. The technician powers on the device and examines the new screen for any defects, such as dead pixels or color inaccuracies. Additionally, they test the touch functionality, ensuring that all areas of the screen respond accurately to touch inputs. Rigorous quality assurance measures help to guarantee customer satisfaction and instill confidence in the longevity of the repair.

Conclusion :

Mobile phone screen installation is a meticulous process that demands precision, expertise, and attention to detail. Skilled technicians adeptly assess the damage, select compatible replacement screens, and employ specialized tools to disassemble and reassemble the device. The success of the repair hinges on the technician’s ability to align and connect

Post time: May-08-2023